In steel fabrication, where meticulous craftsmanship meets cutting-edge technology, precision isn’t just a desirable trait—it’s an absolute necessity. Imagine a skilled machine operator guiding a CNC machine, delicately shaping intricate designs into metal parts with unwavering accuracy. Every cut, every drill, every millimetre matters. In this high-stakes environment, the role of precise sensors, particularly high-accuracy touch probes, emerges as paramount.

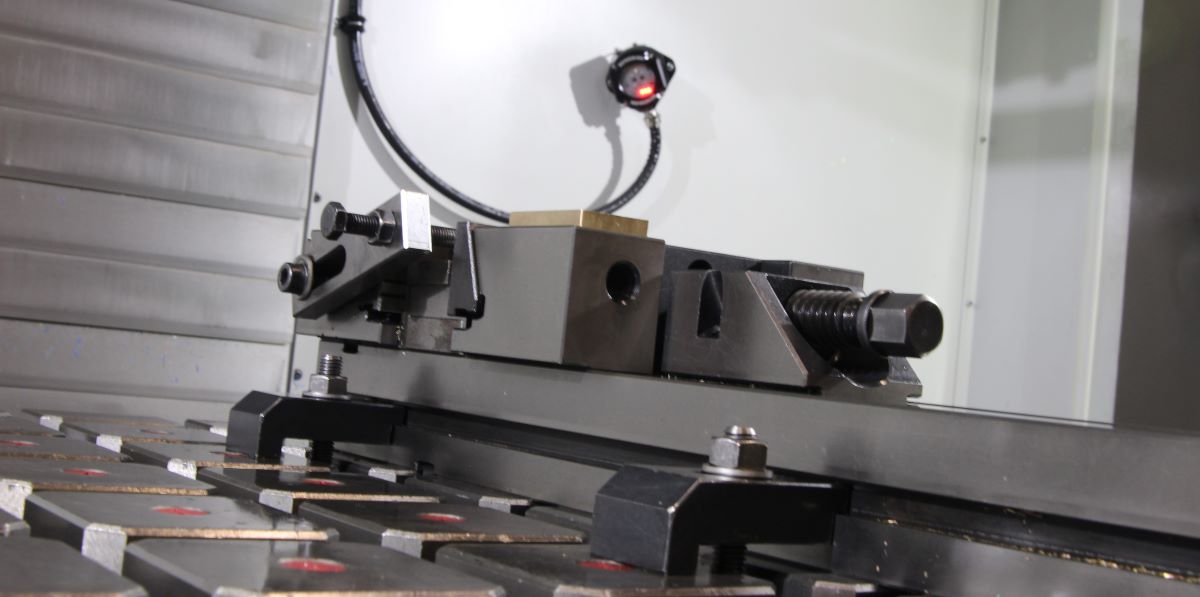

At the heart of CNC machining lies the delicate dance between humans and machines, where the operator’s expertise meets the machine’s precision. However, even the most skilled operator relies on the keen senses and gentle hands of sensors to ensure flawless execution. These sensors, equipped with remarkable 3D sensing capabilities, serve as the guiding light for CNC machines, safeguarding against even the slightest errors that could jeopardise the entire fabrication process.

Renishaw, a global leader in sensor technology, is a shining example of excellence in this field. Their patented strain gauge sensors, powered by RENGAGE™ technology, are the backbone of CNC machines at Wrightform and countless other manufacturing facilities worldwide. These sensors are renowned for their pinpoint accuracy, providing real-time feedback to the machine’s control system, enabling instantaneous adjustments to maintain consistent performance—a crucial feature in the dynamic landscape of steel fabrication.

Strain gauge sensors are not just about precision and adaptability; they are about real-world application. Calibrated to meet the demands of cutting, drilling, milling, and engraving operations, these sensors are the secret behind CNC machines navigating complex shapes and contours with unparalleled precision. They effortlessly achieve the desired outcome, no matter how intricate, making them the go-to choice for precision machining tasks.

Strain gauge sensors are not just about precision and adaptability; they are about durability. Crafted from robust materials capable of withstanding harsh conditions, these sensors endure extreme temperatures, exposure to liquids, vibrations, and mechanical shocks. Whether operating in controlled factory environments or braving the elements outdoors, they remain steadfast in delivering reliable measurements, ensuring consistent performance across diverse machining tasks.

Moreover, these sensors cater to various machine sizes and applications, offering tailored solutions for every need. Engineered for resilience and consistency, they instil confidence in their ability to deliver accurate measurements time and again, regardless of the challenges they encounter.

In CNC machining, where perfection is the ultimate goal, high-accuracy touch probes serve as the guardians of quality. From setting workpieces to guiding machining processes and inspecting final products, these sensors stand as unwavering allies in pursuing excellence. They embody the fusion of human expertise and technological prowess, ensuring that each piece produced meets the most stringent quality standards, leaving no room for error.

The indispensable role of precise sensors, particularly strain gauge sensors, in CNC turning and milling machines for metal fabrication cannot be overstated. They are not just machinery components but the guardians of precision, reliability, and quality, shaping the future of manufacturing one precise measurement at a time.