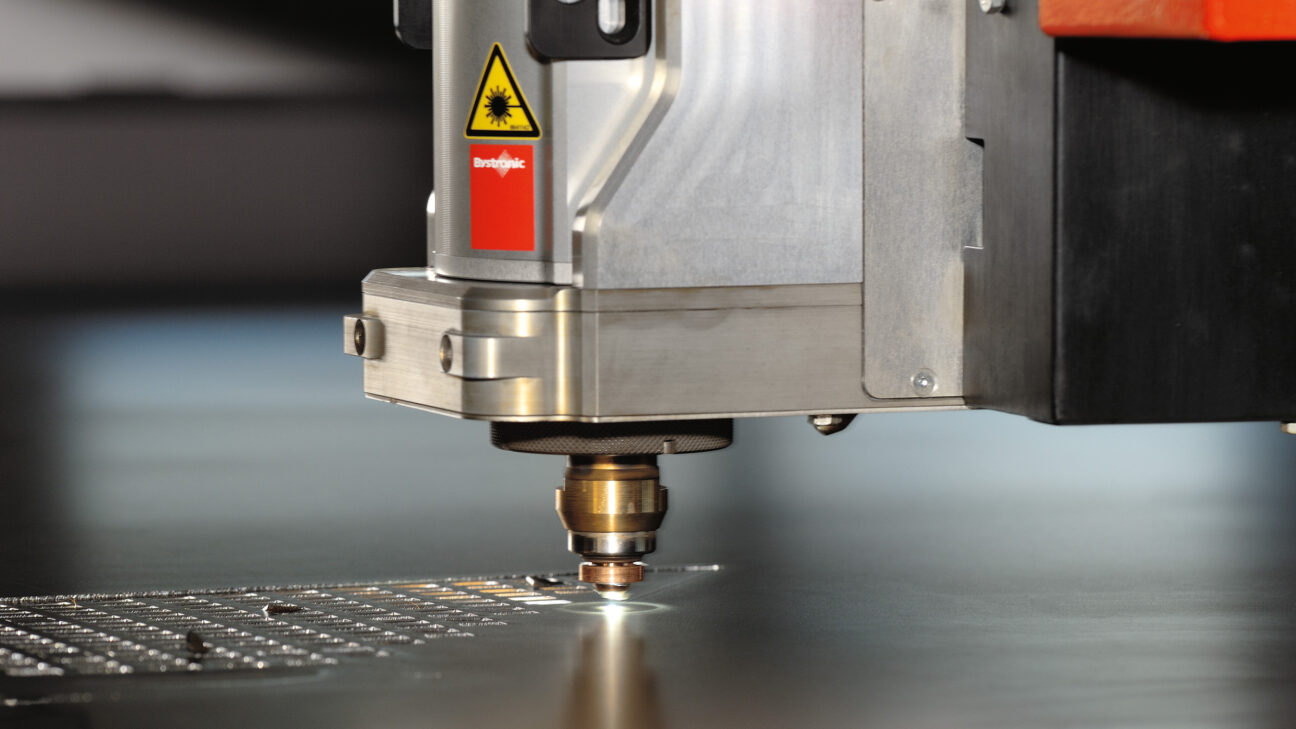

From it’s foundation in 2002 with one 4 kW Co2 laser and one press brake, Wrightform has grown steadily, supplying quality parts to both new and an already established base of satisfied customers.

Incorporated over twenty years ago, Wrightform has grown its business steadily since then by keeping ahead of the game through investing in technology.

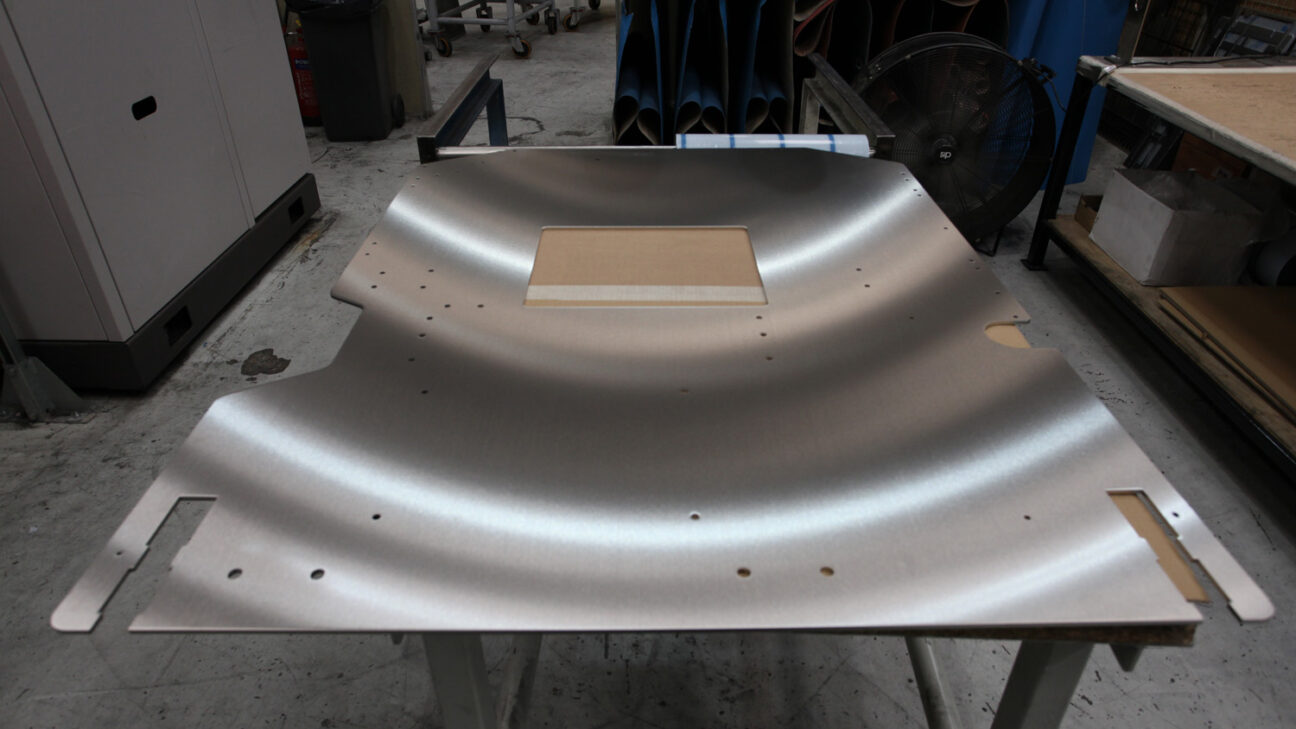

Recently Wrightform extended it’s premises by 6,500 square feet to accommodate our new 15KW fibre laser with sheet feeding automation. Other recent machinery updates include the addition of a press brake with robotics, a rumbling machine and perhaps the largest commercially available metal flattening machine in the country.

This new state of the art equipment is complimented by Wrightform’s existing two lasers, three press brakes, polishing and deburring machines and a host of other machining and fabrication equipment.

To strengthen our green credentials, we have just installed a nitrogen generation plant capable of providing the gas to all three lasers. At the same time ducting was added to transfer the heat from the plantroom into the works.

Wrightforms fleet of fully covered vehicles has been updated and added to enable us to deliver throughout Norfolk, Suffolk, Essex and Cambridgeshire daily. Agreements with local carriers provide logistics covering the rest of the UK.

Our experienced sales and drawing office staff are always on hand to answer any pricing, delivery and technical questions.

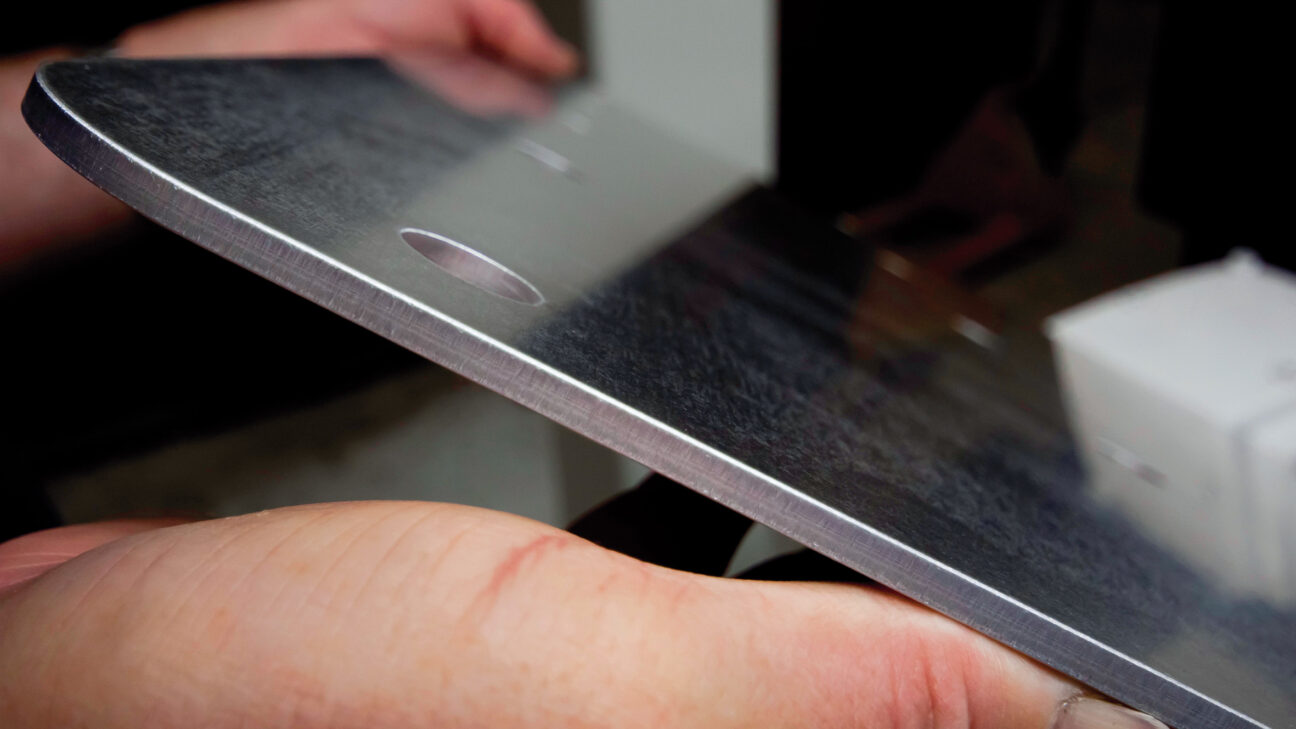

At Wrightform our emphasis is always on quality and the lasers we operate reflect this ethos.

“We continuously update and replace our technology to ensure that our customers benefit from the highest possible quality at the best possible cost.”

wrightform