In the dynamic landscape of manufacturing, efficiency, precision, and flexibility are paramount. For businesses seeking to streamline their operations and optimise productivity, subcontracting options emerge as a sound strategic choice.

While some may ponder the feasibility of outsourcing such a critical process, the benefits are profound and far-reaching. Let’s take a brief look into why businesses should consider leveraging the expertise of subcontractors for their sheet metal laser-cutting needs.

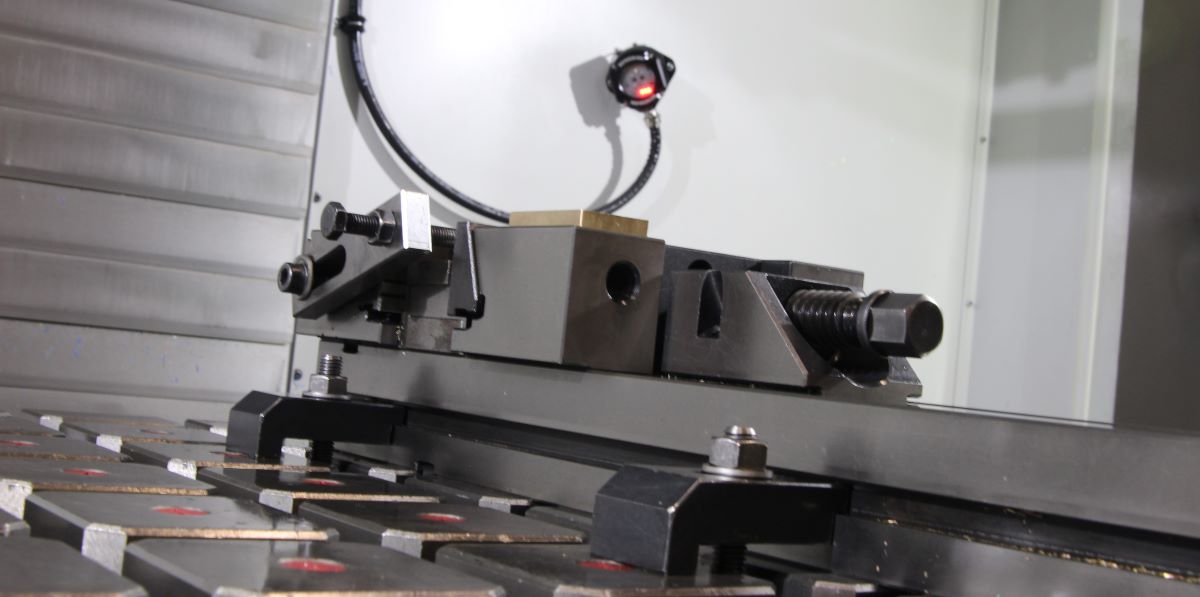

Access to Cutting-Edge Technology

Subcontracting sheet metal laser cutting offers businesses immediate access to cutting-edge technology without the hefty investment required for in-house equipment. Laser cutting machines continue to evolve, incorporating advanced features that enhance speed, accuracy, and versatility. Machines can cut a variety of materials which are 25 mm thick and beyond! By partnering with a reputable subcontractor, businesses can tap into this technology, ensuring that their components are made with the latest advancements in laser cutting technology.

Specialist Expertise and Experience

There is no substitute for experience and sheet metal laser cutting is both an art and a science, requiring specialist skills and expertise to achieve optimal results. Subcontractors dedicated to laser cutting possess a wealth of experience and knowledge. Their teams of skilled technicians understand the intricacies of laser cutting, from material properties to machine settings, ensuring precise and consistent outcomes for every project.

Cost-Effectiveness and Scalability

Outsourcing sheet metal laser cutting to a subcontractor can yield significant cost savings compared to maintaining an in-house cutting facility. Subcontractors spread their overhead costs across multiple clients, resulting in lower per-unit costs for each project. Laser machines also come with high energy costs so running a laser cutting machine can be expensive. Another advantage is that subcontracting can offer scalability, allowing businesses to scale their production capacity up or down according to demand without being burdened by fixed overhead costs.

Focus on Core Competencies

By entrusting sheet metal laser cutting to a subcontractor, businesses can redirect their resources and focus on their core competencies and strategic initiatives. Outsourcing non-core activities such as laser cutting frees up valuable time and resources, enabling businesses to innovate, expand, and differentiate themselves in the marketplace.

Faster Turnaround Times

Time is of the essence in today’s fast-paced business environment. Subcontracting sheet metal laser cutting enables businesses to accelerate their production timelines and meet tight deadlines with ease. With dedicated resources and streamlined processes, subcontractors can complete projects swiftly and efficiently, ensuring prompt delivery of components to customers.

Quality Assurance and Consistency

Reputable subcontractors adhere to stringent quality control measures to uphold the highest standards of quality and consistency. From initial material inspection to final pre-packaging checks, every step of the laser cutting process is meticulously monitored to ensure accuracy, precision, and adherence to specifications. By partnering with a trusted subcontractor, businesses can be rest assured that their components will meet or exceed their expectations, bolstering their reputation for excellence.

Risk Mitigation and Compliance

Outsourcing sheet metal laser cutting to a subcontractor mitigates risks associated with equipment maintenance, technological obsolescence, and regulatory compliance. Subcontractors invest in state-of-the-art equipment and stay abreast of industry regulations and standards, ensuring compliance and minimising operational risks for their clients.

Subcontracting sheet metal laser cutting offers a multitude of benefits for businesses seeking to optimise their manufacturing processes and drive success. From access to cutting-edge technology and specialised expertise to cost-effectiveness and scalability, the advantages are undeniable. By partnering with a reputable subcontractor, businesses can unlock efficiency, precision, and competitiveness, propelling them towards sustainable growth and prosperity in the ever-evolving marketplace.

If you would like to discuss any of our metal laser cutting services, Please get in touch if you have any questions.