In the dynamic realm of technological progress, metal fabrication emerges as a silent yet thrilling force, propelling industries like aerospace, automotive and agriculture towards uncharted territories. From the sleek fuselage of a supersonic jet to the robust chassis of an electric vehicle, metal fabrication, with its innovative techniques and cutting-edge technology, plays a pivotal role in shaping the future of transportation, exploration, and innovation.

Metal Fabrication in Aerospace

Aerospace engineering demands unwavering precision, unyielding durability, and uncompromising reliability, qualities that are inherently embedded in metal fabrication processes. Aircraft components such as wings, fuselages, and engine parts rely on advanced metal fabrication techniques, which are trusted for their ability to meet stringent safety and performance standards. High-strength aluminium alloys and composite materials are meticulously fabricated into aerodynamic shapes, ensuring optimal aerodynamic efficiency and structural integrity.

Furthermore, metal fabrication enables the production of complex structures like turbine blades and engine casings, critical components in aircraft propulsion systems. Advanced machining, welding, and additive manufacturing techniques empower aerospace engineers to push the boundaries of design complexity, allowing for lighter, more fuel-efficient aircraft with enhanced performance capabilities.

Metal Fabrication in the Automotive Sector

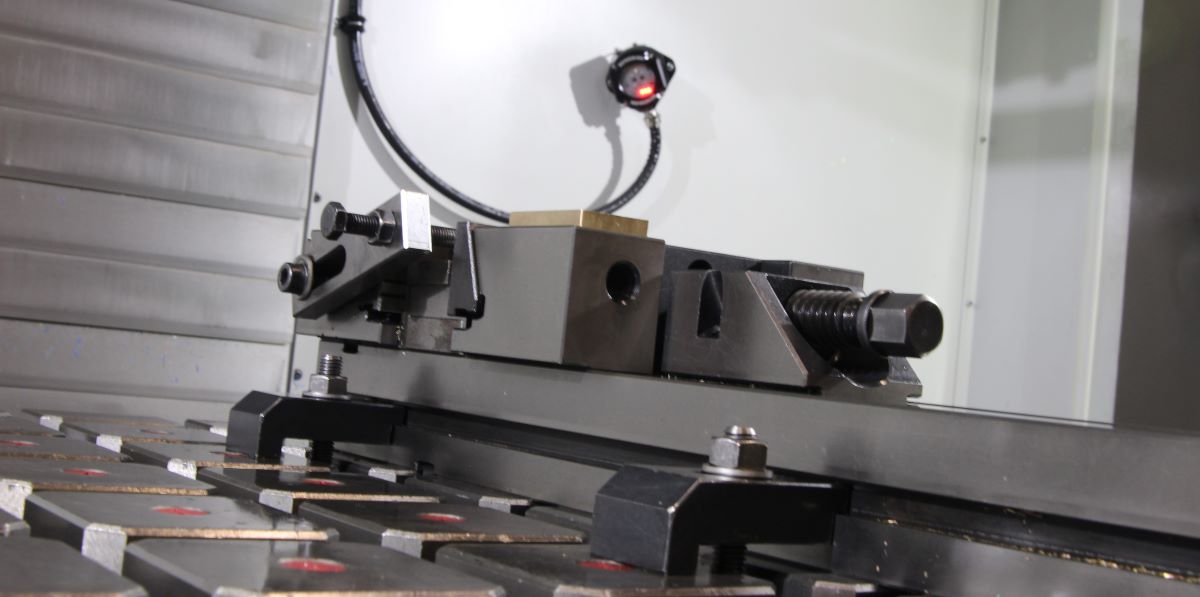

In the automotive industry, metal fabrication is the backbone of vehicle manufacturing, providing the structural framework and aesthetic appeal defining modern cars and automobiles. Metal fabrication processes are integral to every stage of vehicle production, from the chassis and body panels to intricate components.

Advanced stamping, forming, and welding techniques shape sheet metal into precise contours, resulting in lightweight yet resilient vehicle structures. High-strength steel alloys, aluminium, and advanced composites are strategically employed to optimise strength-to-weight ratios, enhancing safety, fuel efficiency, and performance.

Metal fabrication also facilitates the integration of cutting-edge technologies such as electric propulsion systems and autonomous driving features. Battery enclosures, motor housings, and sensor mounts are meticulously crafted using innovative fabrication methods, supporting the transition towards sustainable, intelligent transportation solutions.

Metal Fabrication in the Agricultural Sector

Metal fabrication plays a pivotal role in modern agricultural practices, providing essential equipment and structures that contribute to farm efficiency and productivity. From fabricating sturdy machinery like tractors, ploughs, and harvesters to creating precision components for irrigation systems and handling equipment, metal fabrication enables farmers to streamline their operations and optimise yields. Additionally, custom-designed structures such as storage silos, greenhouses, and livestock shelters are fabricated to withstand harsh environmental conditions, safeguarding crops and livestock while minimising waste.

Beyond the Aerospace, Automotive and Agricultural industries

While these industry sectors serve as prominent examples, the impact of metal fabrication extends far beyond these sectors, permeating virtually every aspect of modern life. In architecture and construction, structural steel fabrication enables the creation of iconic buildings, bridges, and landmarks, showcasing the versatility and strength of metal as a building material.

In the energy sector, metal fabrication supports the development of renewable energy infrastructure, including wind turbines, solar panels, and hydroelectric facilities. Precision-engineered components such as turbine blades and solar panel frames are instrumental in harnessing clean energy sources and reducing reliance on fossil fuels.

Metal fabrication is the backbone of progress, driving innovation and transformation across many industry sectors. With its ability to transform raw materials into intricate structures and components, metal fabrication empowers engineers, designers, and manufacturers to push the boundaries of what is possible, shaping a future of efficiency, sustainability, and technological excellence. As we continue to explore new horizons and confront global challenges, the impact of metal fabrication will remain at the forefront of human ingenuity, guiding us towards a brighter, more resilient world.

Please contact us if you’d like to chat with a Wrightform representative if you are interested in any metal fabrication services.